Made to order from 1 to 10,000 pieces on demand

One-on-one support service Response within 12 hours

In-house machine shop, 24/7 operations, Quick turnaround

Wide range of machining technicals. Tight tolerances, Finer surface finishes.

ISO 9001:2015 certified 100% part inspection

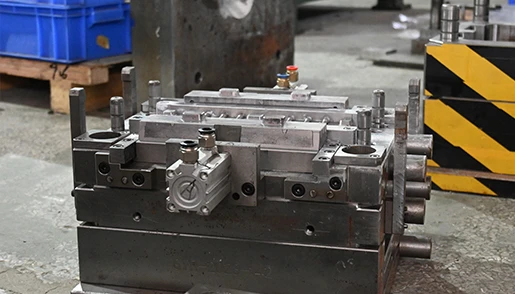

Our Rapid Tooling Service

Rapid tooling is used for producing low-volume quality production parts and prototypes from real materials, which streamlines the product development process, making it faster and more cost-effective while allowing for greater design flexibility. IDEAL offer full low-volume production and rapid tooling service.

Advantages of Rapid Tooling

Design Flexibility and Customization

Designers can quickly iterate and refine designs, allowing for adjustments based on testing and feedback without extensive rework. Rapid tooling allows for easy customization of tools and parts, meeting specific customer needs without extensive retooling.

Limited Volume and Faster Time

Whether you are rapid prototyping or simply have a tight deadline to meet, the prototype mold process allows for quicker turnaround with parts in your hand in as little as 10 business days! Ideal for projects where a limited run of high-quality parts is needed. Great for quantities up to 10,000-50,000 depending on tooling used.

Rapid tooling significantly shortens the time required to create molds and tools, enabling faster product development cycles

Break-Even Costs

With low piece pricing at high quantities, the cost of molding, in many instances, outweighs the costs of other rapid prototyping processes such as Additive Manufacturing. Tooling used is optimized for smaller runs and is typically made of cheaper materials, is less complex, and thus less expensive to produce.

Material Variety

It supports a wide range of materials, including metals, plastics, and composites, providing flexibility in choosing the right material for the application.

Common Types of Rapid Tooling

Aluminum Tooling/Prototoype Tooling

This is the ideal choice for prototype injection molding because it is a cost-effective means of producing injection molded parts. Using aluminum ensures dimensional stability in the mold tooling, significantly reducing waste production and part deformation during production. Aluminum molds are also easier to cut, thereby reducing tooling costs by up to 25%. Using aluminum molds also reduces cycle times by 30-40%. All of these combine to ensure faster turnarounds.

Steel Tooling/Rapid Injection Tooling

Steel is a high-quality, solid, and sturdy material with a longer life cycle. It is more suitable for high-volume production runs and for producing molds from engineering-grade plastics. Despite its long life cycle, it is more expensive than aluminum and may require more time to produce mold tooling and prototypes.

Discover more of Steel Tooling/Rapid Injection Tooling

Why Choose Rapid Tooling Service From IDEAL?

Competitive Prices. Our expert engineers combine advanced techniques with the right materials to give cost-effective solutions. With a better knowledge of rapid tooling designs and material selection, we ensure high-quality molds at the lowest possible price.

Design for Manufacturing Support. As part of prototype injection molding process, we offer design for manufacturing (DFM) support to reveal any issues with your design. Thus, you can make the required changes before prototyping or production begins. This will help save costs.

Timely Delivery and Quality Assurance. The right combination of technologies and experience results in faster production of prototypes for functional testing. The speed reduces the time you will spend in the prototyping stage, ensuring faster time to market. IDEAL adhere to international quality standards, and you can often find companies that provide comprehensive quality control measures.

Access to a Wide Range of Capabilities and Strong Supply Chain. WIth a well-established supply chain, IDEAL combined technologies like CNC machining, EDM machining, 3D printing, vacuum casting and finishing experiences in product development, can produce rapid production tooling and rapid injection mold quickly and efficiently.

Communication and 24/7 Support. Highly skiled English and customer service, making collaboration easier.

Rapid Tooling Plastic Materials

Plastic injection molding service comes with a wide range of materials with different properties, including impact strength, rigidity, thermal resistance, chemical resistance, etc.

| ABS | Nylon (PA) | PC | PU |

| PMMA | PP | PE | HDP |

| EPS | PC | PVC | PEEK |

| POM | ABS/PC | PETG | PS |

| LDPE | HDPE | PPA | PSU |

| Fluorosilicone | PET | PPE | |

| (fuel and oil resistant) | Standard silicone | ||

| Medical-grade silicone | Optical-grade silicone |

How Rapid Tooling Works?

Optimized Design for Manufacturability (DFM)

We incorporate design for manufacturability (DFM) into every aspect of the injection molding process, from part design to injection mold tooling, materials selection, and machining process. No need to wait until production to reveal issues with the design. Our optimized design for manufacturability ensures cost-effective tooling and molding of parts to scale.

Tooling Method and Material Selection

Typically uses metals (e.g., aluminum, steel) or hard plastics.

Tool Steel

D2 Steel: High carbon, high chromium steel; excellent wear resistance; suitable for durable molds.

A2 Steel: Air-hardening steel with good toughness and dimensional stability; suitable for precision tooling.

P20 Steel: Pre-hardened tool steel; good for low to medium volume production and can be machined easily.

Stainless Steel Corrosion-resistant steel often used in specific applications where moisture or chemicals are present. Offers durability and resistance to corrosion; suitable for medical or food industry applications.

Aluminum Alloys Used for quick tooling due to its lighter weight and ease of machining. Lower costs, faster production times, and good thermal conductivity; suitable for prototype molds or low-volume production.

Tooling Production and Mold Assembly

Manufacturing: The selected rapid tooling method is used to produce the mold or tooling inserts. The mold is machined to create the cavity that will shape the part. This involves precision work using CNC machines.

Integration: If required, the rapid tooling inserts are assembled into a complete mold base, including features like cooling channels.

Injection Process: Once the mold is ready, it is used in the injection molding machine to produce parts.

T1 Sample Improvement and Final Sample Approvement

With the newly made molds, we make a T1 sample to have a clear vision of how the customer's final molded parts will turn out.

We provide Improvement if necessary based on our analysis of the T1 sample, we review the mold design and make any adjustments needed. Upon the approval of new sample, the remaining parts are made and shipped.

Production Run and Post-Processing

Material Injection: Molten material (e.g., plastic resin) is injected into the mold cavity under high pressure.

Cooling and Ejection: The material cools and solidifies within the mold cavity, and the part is ejected once solidified.

Cycle Repetition: The injection process can be repeated for large production runs, with minimal downtime for maintenance.

Finishing Touches: Additional processes may include trimming excess material, painting, or adding surface finishes.

Have any Questions or Suggestions? We would love to help you! Talk to us!

Rapid Injection Tooling Considerations

Rapid Injection Tooling Considerations

Tool Material & Tool Life

Tooling used for prototype molding applications is generally made of softer materials and thus will wear out sooner than molds made of tougher material, typically made of steel such as P20 Steel, 718H. Additional maintenance may be required before 10,000 shots are performed.

Part Material & Mold Texturing

Texturing and polishing of rapid molds can be performed, and IDEAL can running multiple colors on the same order.

All of our usual injection molding material offerings are available for prototype molding!

Gating Options

Gates may be constrained to edge, direct & fan techniques. Gating that requires high shear or hot runners is better suited for Bridge or Production tooling.

Basic gate strategies like edge, direct, and fan gating, bridge tools may also utilize hot-runners or hot manifold systems to meet the project requirements. High shear applications are also suitable.

Tool Origin

IDEAL offers both China-based molding and also international molding options.

Leading Time

IDEAL can typically deliver a prototype injection mold component within 3-5 weeks, and Our engineers and project managers will work with you to develop a more detailed timeline with weekly progress staus.

Rapid Injection Tooling Considerations

Tool Material & Tool Life

Generally made of softer materials in prototype grade aluminum molds, Up to 2,500 shots.

Part Material & Mold Texturing

Dozens of production-grade material options to choose from, and 6 Standard finishes (SPI-A2, A3, B2, B3, light or heavy textured) are available.

Gating Options

Gates may be constrained to edge, direct & fan techniques. Gating that requires high shear or hot runners is better suited for Rapid Tooling or Production tooling.

Tool Origin

China-based molding.

Leading Time

IDEAL can typically deliver a prototype injection mold component within 3 weeks, and we will provide weekly progress staus.

Rapid Injection Molded Parts Surface Finishes

For most of the injection molded parts, no post-processing is needed. This is because the mold itself are usually finished to different levels and directly affect the surface finish of molded parts.

Glossy Finishing

A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces.

SPI Standard: A1, A2, A3

Semi-Glossy

B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Products that undergo B grade finishing have a matte surface texture.

SPI Standard: B1, B2, B3

Matte

C grade finishes use grit sanding stones to produce a rough, uneven surface. Products that undergo C grade finishing have a matte surface texture.

SPI Standard: C1, C2, C3

Textured

D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish.

SPI Standard: D1, D2, D3

Rapid Tooling FAQ

Q: Why Should I Use Rapid Tooling?

A:

Rapid tooling is a fast and cost-efficient way to create a few prototypes in a selected material for function and aspect testing, as well as for low-volume manufacturing to test out the market.

Q: How Fast Can I Get The Moldings?

A:

This depends on the size and geometry of the parts. For a common open and shut mold with regular size part such as 300 x 300 x 50 mm, fabrication of tools and moldings can be done within 10 days.

Q: What Materials Can I Choose From With Rapid Tooling?

A:

There is no limit to material choice. Any plastics available for mass production, including common silicone and rubber materials, can also be used with the rapid tooling process.

Q: What Is The Quality Level Of Rapid Tooling?

A:

Moldings from rapid tooling are end-use-parts quality. They are very close to mass production parts.

The quality level of rapid tooling can vary significantly based on several factors, including the specific methods used, materials chosen, and the skill of the technicians involved. Here are some key points to consider. For specific projects, it's best to consult with IDEAL to understand their capabilities and the quality level they can provide for your particular needs.

Q: How Many Moldings Can I Get From Rapid Tooling?

A:

Normally, aluminum molds are good enough for +/- 1,000 shots, while Steel P20 molds can last for +/- 10,000 shots.

The number of moldings you can obtain from rapid tooling depends on several factors, including:

Material of the Mold: Different materials (e.g., aluminum, steel, or thermoplastics) have different durability and lifespans.

Complexity of the Part: More complex designs may affect the number of successful moldings.

Type of Production: Continuous production runs will yield more parts compared to one-off prototypes.

Molding Process Used: Certain processes may wear out the mold faster than others.

To get a more precise estimate, it's advisable to consult with IDEAL consider your specific project requirements.

Q: How Reduce Injection Molding Costs?

A:

1. Design parts without undercuts. 2. Delete unnecessary part features, and keep a constant wall thickness. 3. Use multi-Cavity molds, interchangeable inserts, and require proper tolerance class.

Request Your Free CNC Machining Quote Today

Our improved algorithm decreases metal 5-Axis CNC Machining quotation times by up to 90%. Most quotes are delivered within 24 hrs. and usually much less, depending on project details.

Your customer support partner will contact you directly to ensure you've received and understand all aspects of your quotation and to answer any questions you may have.

Rapid Tooling Cases

Quickly and costly get your molded parts with the production-grade material and technology process by using the rapid tooling,for low volume rapid injection molding.

See What Our Custom Say

My experience working with Fay was great.Clear communication that put me at ease. Very easy to order these parts. Great quality and werecieved exactly what we were expecting - Followed the engineered drawings precisely. Theproduct arrived well packaged, and precisely to spec.

Thank you very much for your consideration and problem solving. lt says a lot about your companyand 1feel comfortable working with you moving forward.

Chris

R&D Manager

IDEAL was able to deliver an accurate and quick service for high quality CNC parts. We inspected the parts, everything was within tolerance in terms of dimensions, and the surface finish on the machined faces is really good. IDEAL has always given us exactly what we needed.

Dennis J.

Engineer

Partnering with IDEAL has transformed our production process. Their precision, reliability, and commitment toquality have been game-changers for us. We've seen a remarkable improvement in efficiency and productquality, allowing us to meet our customers' demands better than ever. IDEAL's team truly understands oulneeds and consistently delivers beyond our expectations.

Jennie Elp.

Senior Mechanical Designer

Latest News

3D Printing: Process, Pros & Cons, and Applications

Feb. 21, 2025

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by adding material layer by layer, based on a digital model. Unlike traditional manufacturing methods, which often involve subtracting material (like cutting or milling), 3D printing builds objects up from scratch, which allows for more complex and

Get Your Parts Into Production Today!

Meeting Your Needs, Solving Your Problems - We're Here to Make CNC Machining Hassle-Free!

GET IN TOUCH WITH US

Navigation

RESOURCE

Contact Us

Tel: 0755-36957776

E-mail: info@idealrp.com

Skype: +86 135 2877 3620

Whatsapp: +86 135 2877 3620

Add.: Shenghua Building, Songgang, Bao'an,Shenzhen 518105

Add.: Room 4, 16/F, Ho King Commercial Building, 2-16 Fa Yuen Street, Mong Kok, Kowloon, Hong Kong